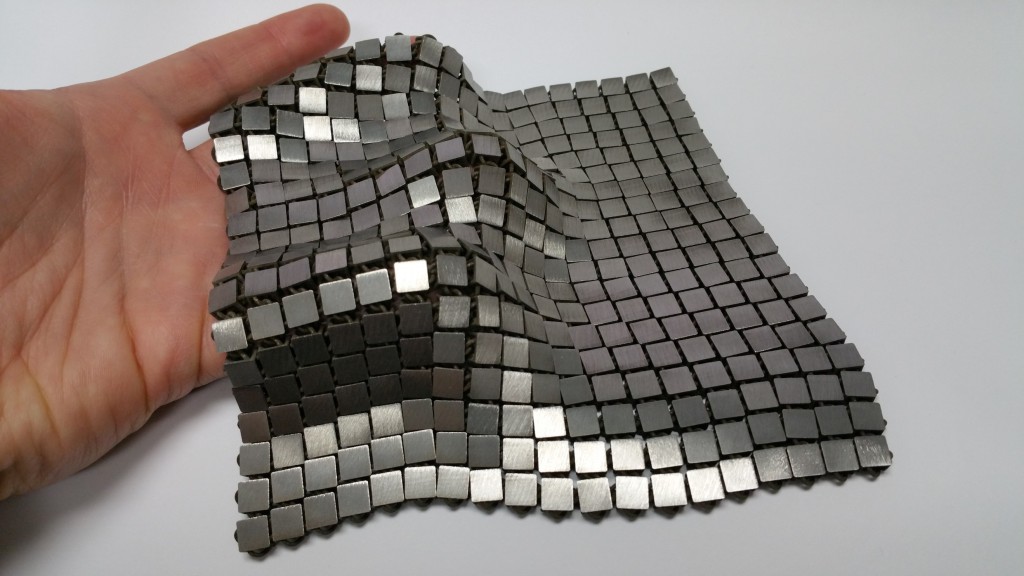

“Space Fabric” – Courtesy NASA/JPL-Caltech

Friday, Oct. 6th, was the first National Manufacturing Day a celebration to promote modern manufacturing and the value it brings to the economy. It was a remarkable success, so much that it has now become National Manufacturing Month. So, let’s add into the effort!

Changing the way we make things

Additive Manufacturing, also referred to as 3D-Printing, is a set of technologies used in prototyping design and production operations that has been the result of innovation from the get go.

Starting by the core process that gives it the name. Instead of building parts by the traditional “subtractive” method, these processes build the parts by adding material as you make it. It starts with a digital 3D model that gets fed to a “3D-printer” to obtain the final desired object. Way to change the game!

That ability to innovate and solve the challenges and needs, of the end-users it serves, is propelling the rapid development of the technology in the recent years, bringing it from rapid prototyping and the tool shop to the production floor, and even beyond: to space!

The explosion of digital-model based data and open source software, along with the expiration of the original patents describing the core processes, have opened the entry window for additional manufacturers of 3D printers, making the cost more affordable and expanding the areas of application.

Not only that. In the last 10 years, several new processes that are reducing the time to make objects have been developed and are being commercialized. For example, In the case of polymers or plastic materials, the latest generations of desktop printers, and combined systems for new small-scale manufacturing, are propelling the change.

So, what are the key attributes that make these set of technologies enticing?

Enables print to order, or “on demand” printing

Perhaps this was the initial benefit that was sought for rapid prototyping. AM effectively cuts the time it takes to develop the next generation of products. You can visualize it, make it, test it and improve upon at a much faster pace. Making it a great tool for design and new product development!

This also helps to streamline the supply chain and eliminates in many cases the need for large warehouses and logistics associated with traditional production methods.

Delivers complex shapes in “one step”

All of a sudden, geometry is not constrained. Objects and parts can be built with voids, which in turn makes them lighter; or you can combine materials, making composites in a single operation.

Furthermore, components that before required additional processes, whether welding or using glue, could be designed from the get go as one single object. Now talk about lean manufacturing!

Ultimate customization

Unique shapes and unique materials to produce one of a kind. From the fashion and jewelry industries to medical applications. For example, individual prosthetics for orthopedic implants. This attribute is for sure a delighter!

So, what do we print next? 4D-Printing

Imagination is the new limit and according to Polit Cassillas, the researcher co-leading Nasa, Jet Propulsion Laboratory, get ready for 4D-Printing, which consists on printing the geometry and the function of those materials.

Click the space link to find more about it!

Marga is a technology leader with an international background and a passion for innovation. During the last 20 years she has grown her expertise in research and business development, focused in industrial and manufacturing applications of polymer and materials science, bringing technologies to commercialization in multiple markets. She holds a PhD, is the inventor of several patents and a published author in technical, trade and conference proceedings over her career.