Prototyping Responsibly

Just looking at you, I can already tell you’re a responsible person. I mean, you’re reading a blog about innovation, for crying out loud — you don’t wind up here if you don’t have all your ducks in a row.

But despite your earnest attempts to live a respectable, dependable lifestyle of two-minute tooth brushing and a measurable commitment to reducing your carbon footprint, there’s still something you’re doing that’s terribly irresponsible. Terribly irresponsible indeed.

You see, while you may have taken the (quite responsible) step of leaning into new innovation techniques, design thinking methodologies, and co-creation sprints, you may be throwing far too many resources into your efforts. In short, you’re prototyping irresponsibly.

But wait, you complain — how can this be? Our prototypes of new products and services do a wonderful job conveying our new ideas to customers. What’s wrong with that?

Nothing, except almost all innovation teams waste a huge amount of time, effort and resources building prototypes that could be done with a fraction of the effort.

That’s the point that Lee Moreau of Continuum makes, noting his company’s experience with leading clients through the rapid prototyping process. All too often, we’re tempted to treat our prototypes as early versions of the future, fully-built out version — isn’t that what they’re supposed to be?

Not quite, says Moreau. Instead of treating a prototype like an early version of eventually successful product, treat it like something you’re going to have to radically rebuild a hundred times. Suddenly, putting a lot of work past the bare minimum starts seeming a lot less efficient.

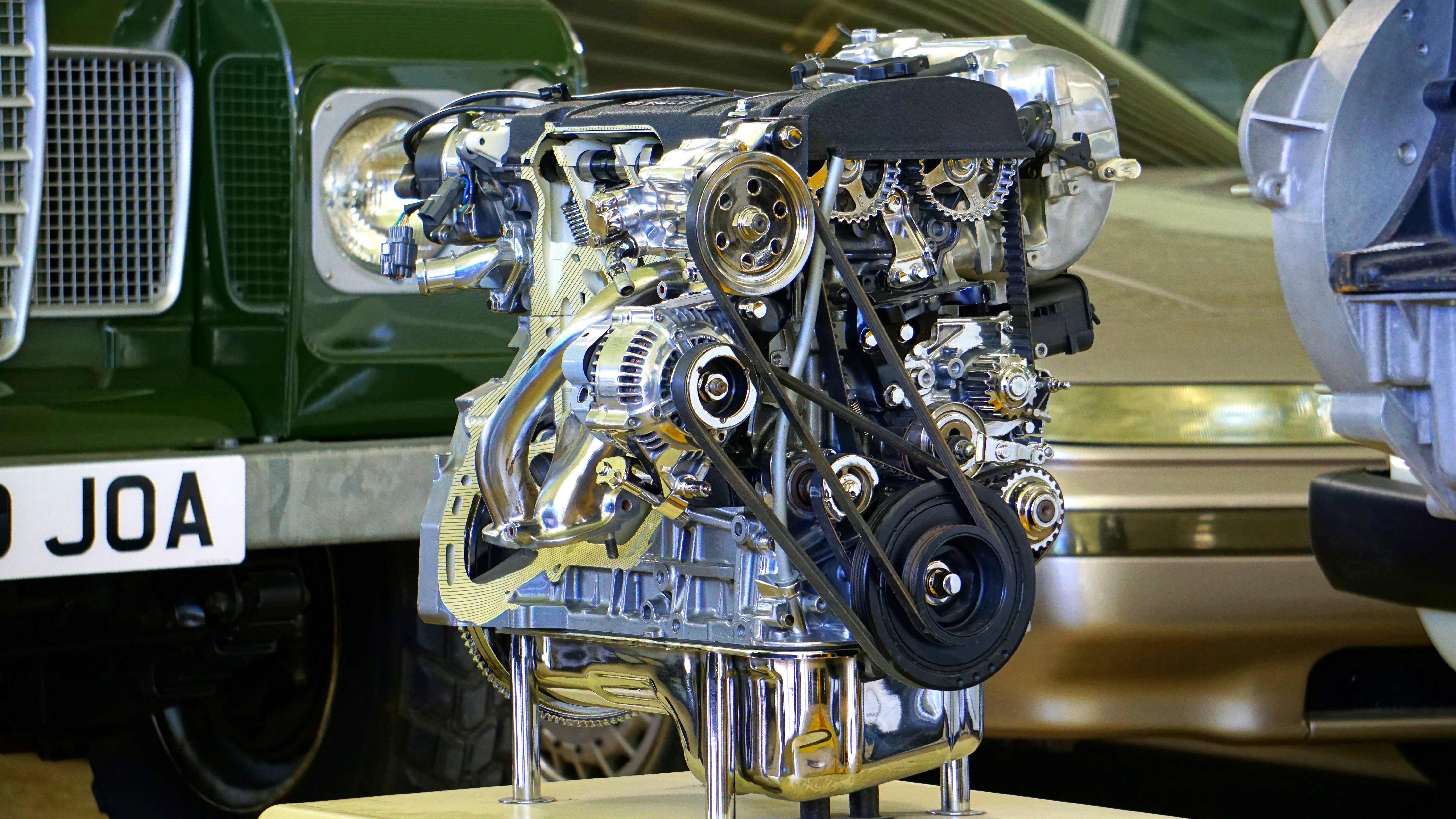

Of course, there’s a balance here. If your prototype for a car engine is made of popsicle sticks, you might have gone too far in the cost-saving direction. (Then again, depending on stage and your skill with popsicle sticks, maybe not.) The goal is to find the lowest-fidelity version of a concept you can create that still makes the experience just real enough for the consumer to give valid feedback. As long as you’re toeing that line, you’re in good shape.

An example? Moreau’s team worked with Southwest to create a better airport waiting experience, eventually putting working screens and an app in an actual airport. But, instead of starting with a close model or even a low-fi buildout, they did something even easier — creating the whole space in virtual reality.

Now, the Continuum team had great VR capabilities on hand, making this truly the cheapest option for them. For others, VR may not be the answer. Instead, consider hacking together existing services, products, and manual systems to “mock up” your prototype, even if it’s almost unrecognizable from your future vision. If its testing the problem you want to solve, it’s doing its job.

Now, I know you’re a responsible person, so surely you’ve been taking diligent notes on this entire article. In that case, you’re ready to start innovating. Just remember: do it responsibly.